Hello, welcome to Chongqing ATEC Technology Co., Ltd. official website!

12

2021

-

08

High and low temperature hub test chamber of ATEC vehicle

Author:

Latest Solution

2021-08-10

ATEC Evaporative airtight test chamber

The evaporative sealed test chamber is mainly used to measure the fuel evaporative pollutant emissions under the conditions specified by the national standard/European standard/American standard and other regulations.

2021-06-02

25 ℃ linear high and low temperature rapid temperature change (damp heat) test chamber

The linear average of mechanical refrigeration under thermal load requirements reaches 25 degrees

2021-06-02

Thermal vacuum test chamber (a research institute in Hunan)

Adopting advanced heat sink temperature control method, excellent temperature uniformity and conductivity, reaching advanced European standards

2021-06-02

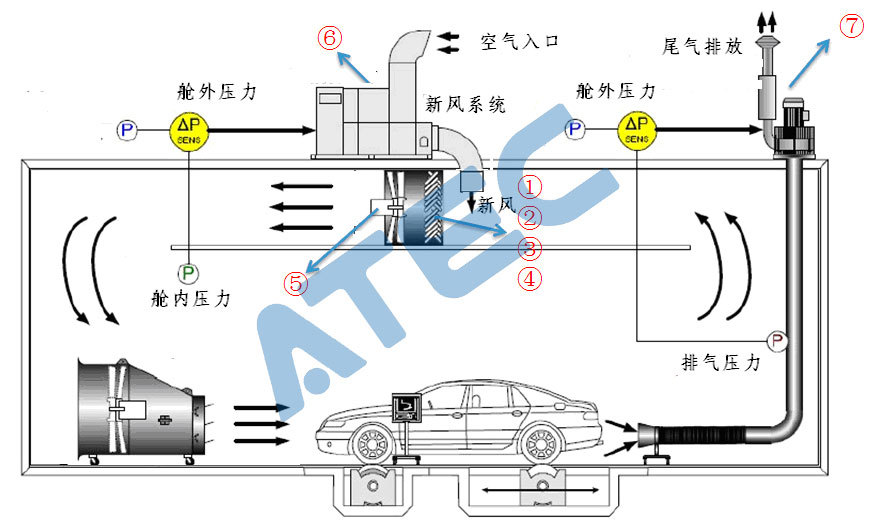

ATEC ATEC Fuel Cell Pipeline Environmental Chamber

ATEC Artest can successfully deliver the fuel cell engine pipeline environmental chamber developed by a heavy-duty automobile group to customers for acceptance. The product aims at the pipeline climate simulation of the fuel cell in the plateau state, realizes the accurate simulation fluctuation test of the plateau temperature, plateau air pressure and plateau oxygen content at the suction end of the fuel cell, and has the hydrogen explosion-proof function of the whole machine. In the process of development, the technical department has overcome several difficulties: 1. to solve the problem of instantaneous generation of large heat during fuel cell operation, which leads to temperature fluctuation in the cabin; 2. Synchronous control of the fuel cell suction demand with the plateau temperature, plateau air pressure and plateau oxygen content of fresh air; 3. When the fuel cell is working, a large exhaust volume is generated instantly, resulting in the stability of the plateau air pressure at the exhaust end. The test system is mainly composed of 8 parts, divided into test chamber, refrigeration unit, fresh air system, control system, discharge system, vacuum system, hydrogen pre-cooling system, explosion-proof safety system. The whole set of equipment has the function of simulating environmental conditions such as temperature, humidity and air pressure in the natural environment. It can simulate and assess the comprehensive superimposed environmental effects such as temperature, humidity and low air pressure often encountered by fuel cell engines. It is suitable for environmental test items of fuel cell engines, temperature and humidity tests of other components, and pipeline height tests. It also meets the following tests for environmental simulation of fuel cell engines with a maximum power of 150KW: low temperature test (low temperature storage, starting, performance); High temperature test (high temperature storage starting, performance); Damp heat test (high temperature and humidity); Temperature altitude test (air pressure simulation); Can be used for cold start test of commercial vehicles.

2021-08-12

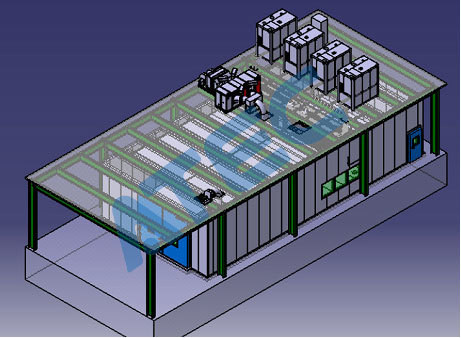

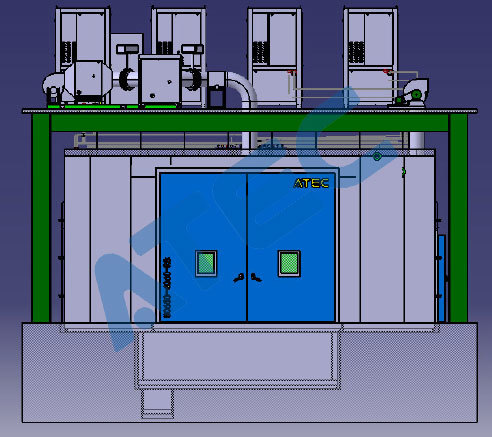

High and low temperature hub test chamber of ATEC vehicle

The hub test chamber is a very important test equipment in the process of automobile product development. Through the hub test, not only the power of the car can be tested, but also the power, economy, comfort and operational stability of multiple working conditions can be measured. Through this technical means to accelerate the development of the automobile industry, narrow the product development cycle, save product development costs, improve the indicators of the car has an important role. This hub test chamber is different from the traditional fuel vehicle hub test chamber. The equipment is specially customized for new energy electric vehicles. It simulates the whole vehicle under real extreme ambient temperature to detect various items of the new energy vehicle battery pack during power test.

渝公网安备50011202502453号

渝公网安备50011202502453号